Head of Synthetic biology and Tissue Engineering Laboratory

Bioengineering and Chemical Engineering Department

Bioprinting is the technology that allows three-dimensional printing of biomaterials loaded with living cells, with the aim of building structures that resemble functional organs and tissues. Combining 3D printing, regenerative medicine and biotechnology, to solve problems present in tissue engineering, pharmaceutical research and medicine.

Despite all the promising advances in the field, new technology is needed that allows the creation of large, clinically relevant grafts, and that they are obtained by a high-speed process.

Current printing methods include inkjet-based techniques, which consist of liquid bioinks that can be extruded by heat into a substrate whose contact will make it structurally rigid. Then laser-assisted bioprinting, in which lasers are used to heat the material and evaporate it before deposition. Finally, lithography-based bioprinting, such as stereolithography (SLA), whose main advantages include high-speed printing and high precision. These technologies take a long time, especially when it is required to generate large, centimeter-scale grafts; which causes the cells to be kept in the bioprinter cartridge for long periods of time, far from an optimal culture environment; generating stress and affecting its functionality.

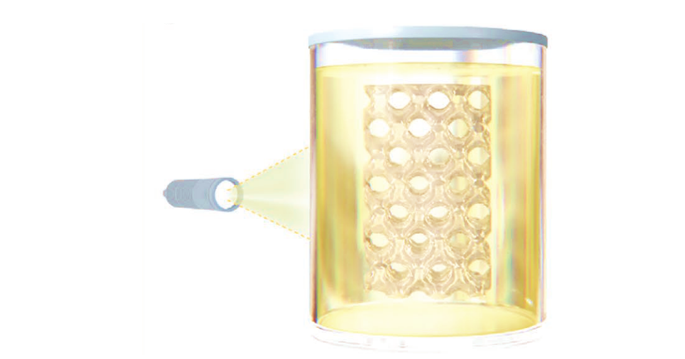

Volumetric bioprinting represents a paradigm shift within bioprinting, offering a revolutionary approach to fabricating complex three-dimensional biological structures. Unlike traditional bioprinting methods that deposit materials layer by layer, volumetric bioprinting leverages techniques that involve the manipulation of lightweight, photosensitive materials to create entire structures at once, rather than by sequentially adding basic building blocks. .

The workflow is similar to bioprinting, starting with a 3D digital model, which was obtained with computer-aided design (CAD) software. The biomaterials with which work are photosensitive, that is, they undergo structural changes when they are exposed to specific wavelengths of light; for example acrylates (methacrylate gelatin) and elastomeric resins, which are worked with a photoinitiator whose concentration must be low enough for light to penetrate through the entire volume, but high enough to allow the gel to polymerize.

Unlike the traditional layering approach, a holographic light projection or multiphoton light polymerization is used, the light patterns intersect within the photosensitive material, a solid structure is instantly formed, shaping the desired 3D structure in a single step After the volumetric printing process, any unreacted material is removed and additional post-processing steps can be performed as necessary.

Bernal et al, 2019, demonstrated that mesenchymal stem cells (MSCs) printed in a trabecular bone model could be maintained in osteogenic medium for 7 days, imitating osteoblasts within native bone (O-MSCs). The complex porous network of the cell-laden trabecular model could also be seeded with additional cells after printing. The researchers introduced endothelial colony-forming cells (ECFCs) and MSCs, to generate a co-culture of osteogenically differentiated cells, vascular endothelial cells and supporting MSCs. After 3 days of culture, they observed the formation of early angiogenic sprouts, typical of the precursors of the blood capillary network.

This suggests that the mesenchymal stem cells differentiated into bone in the bioprinted model have the capacity to provide paracrine signals that promote the angiogenic process driven by ECFCs; thus demonstrating that volumetric bioprinting allows the realization of key cellular functions.

References

- Bernal, P.N. et al. (2022) ‘Volumetric Bioprinting of Organoids and Optically Tuned Hydrogels to Build Liver-Like Metabolic Biofactories’, Advanced Materials, 34(15). Available at: https://doi.org/10.1002/adma.202110054.

- Bernal, P.N. et al. (2019) ‘Volumetric Bioprinting of Complex Living-Tissue Constructs within Seconds’, Advanced Materials, 31(42). Available at: https://doi.org/10.1002/adma.201904209.

- Grottkau, B.E., Hui, Z. and Pang, Y. (2020) ‘A novel 3d bioprinter using directvolumetric dropondemand technology for fabricating micro tissues and drugdelivery’, International Journal of Molecular Sciences, 21(10), pp. 1–11. Available at: https://doi.org/10.3390/ijms21103482.